Regulatory overview

OSHA requirements and explanations

With decades of experience in industrial training solutions, MST now offers comprehensive LOTO training, an important aspect of workplace safety in industrial settings. Proper LOTO safety can prevent accidents, injuries, and even fatalities, and our simulator board and training content ensure students get the hands-on experience they need. Learn more about the benefits of LOTO training!

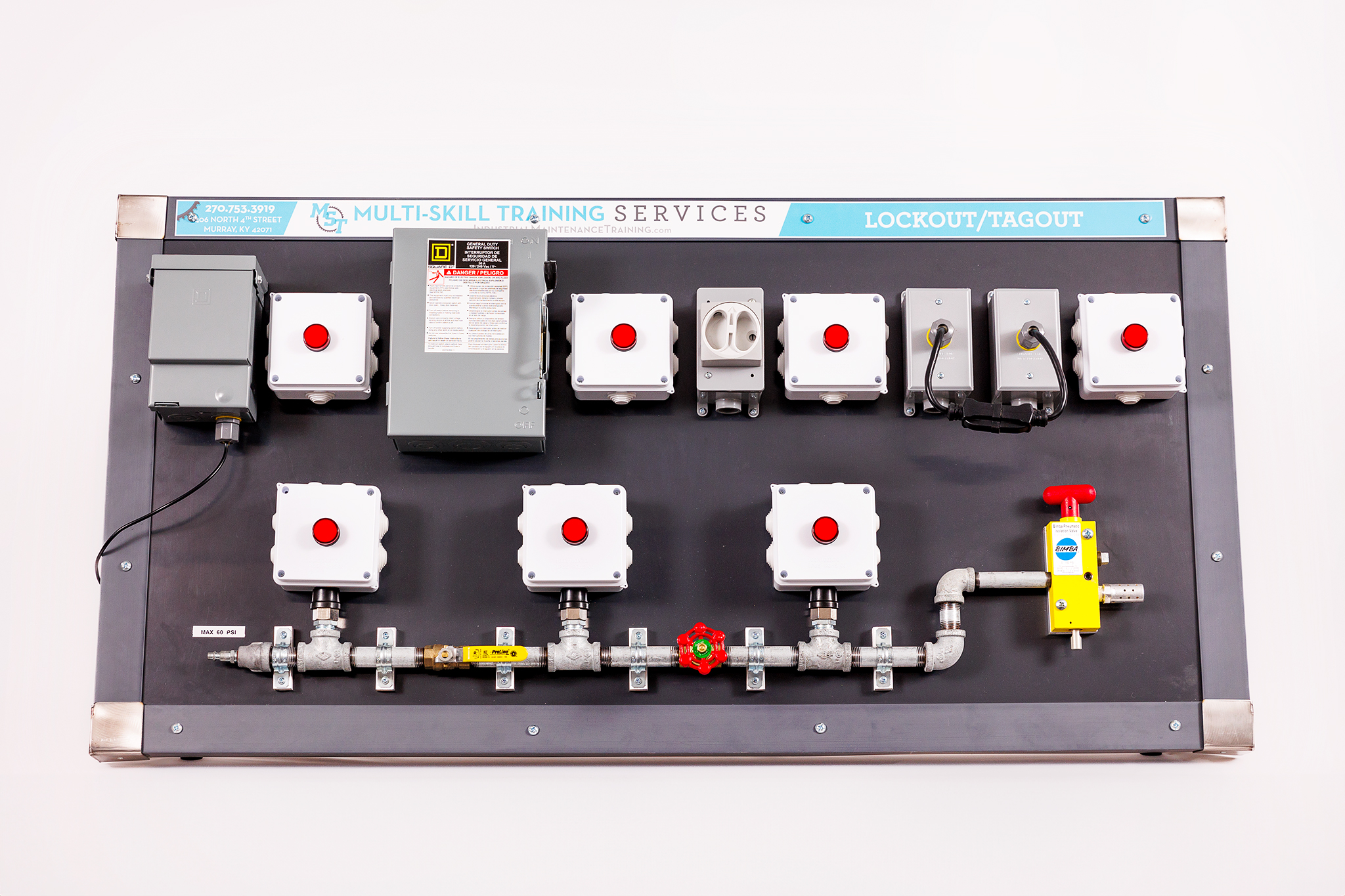

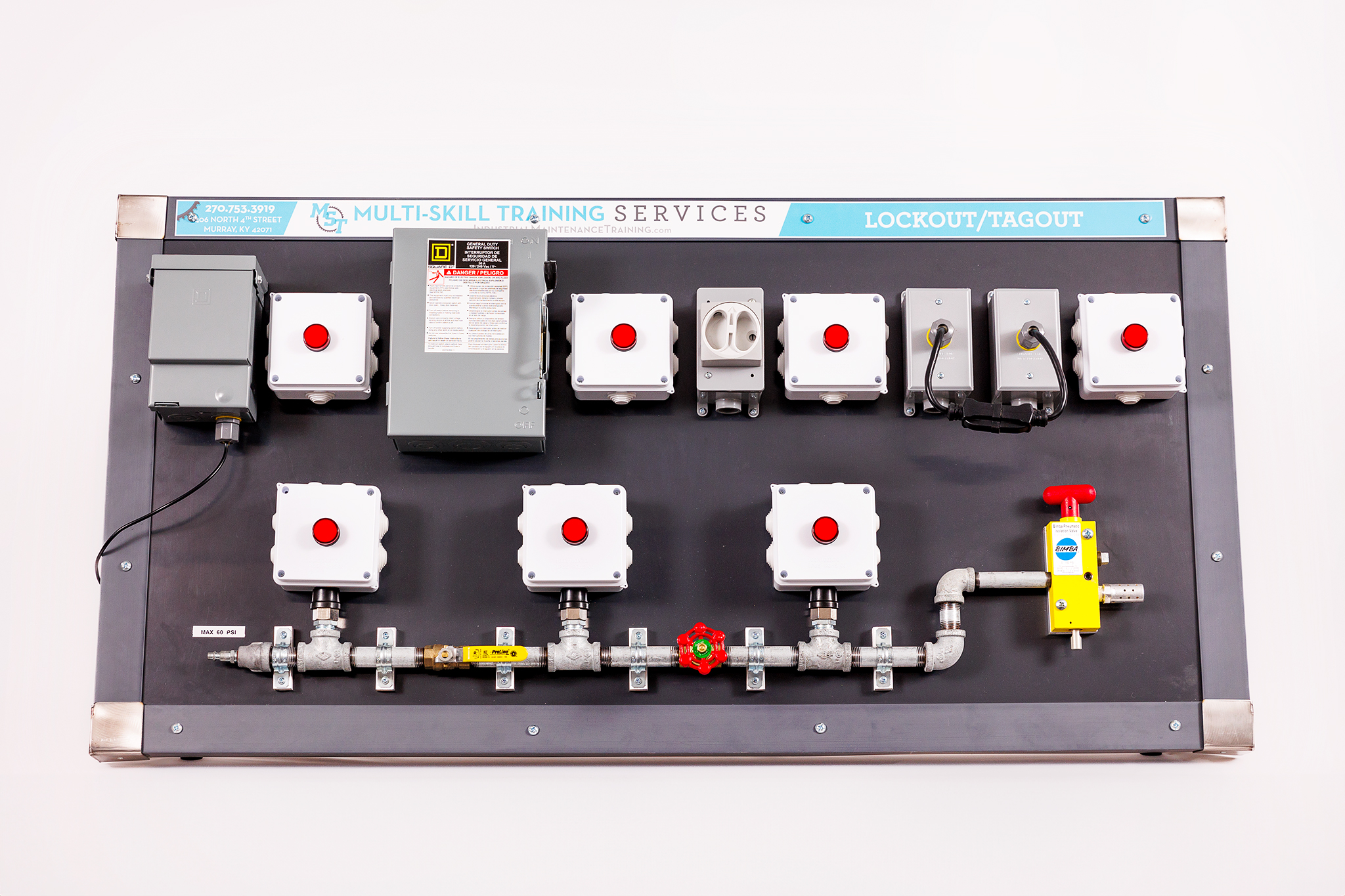

The LOTO trainer divides your Lockout / Tagout Training into two energy sources: Electrical and Pneumatic.

To learn more about our various Industrial Maintenance Training Programs including Maintenance Fundamentals Training, Industrial Electrical Training, Electrical Controls Training, Pneumatics Controls Training, Programmable Logic Control Training, or Analog Controls Training, contact us today.

The Electrical Energy Source exposes students to the machinery electrical supply path within a manufacturing facility. Red pilot lights indicate areas that are still energized within the electrical supply path and allow students to view the results of their LOTO actions.

BREAKER: The electrical supply path starts at the breaker typically located within a secondary breaker panel; breaker is typically located in an electrical room off the production floor.

WALL-MOUNTED DISCONNECT: typically located on the production floor and provides power to the primary machine and any remote equipment.

PANEL MOUNTED DISCONNECT: usually located directly on the control panel door.

CORD-DROP: used for remote attached equipment to the primary machine; allows isolation of remote equipment without removing power to the primary machine.

The Pneumatic Energy Source trainer exposes students to a pneumatic supply path within a manufacturing facility. The pneumatic energy LOTO training allows the stored pneumatic energy to be trapped between valves with this energy demonstrated by red pilot lights on the trainer.

AIR SUPPLY QUICK CONNECTION: this connection demonstrates the use of quick connection and how pneumatic energy is stored only on the female side but not the male side of the quick connect fittings.

BALL VALVE: a ball valve allows students to understand how valve handle positions indicate state and how compressed air can be trapped between valves if not vented through a pneumatic safety lockout valve.

GATE VALVE: like the ball valve, compressed air can be trapped between valves; unlike the ball valve, no visual indication exists of the valve state without turning the gate valve knob.

SECONDARY GATE VALVE: utilizes a rising stem, allowing visual confirmation of valve position; is connected directly to the pneumatic safety lockout valve allowing the stored pneumatic energy to be vented directly.

Let us design the perfect one for you.

© 2025. Multi-Skill Training Services, Inc.