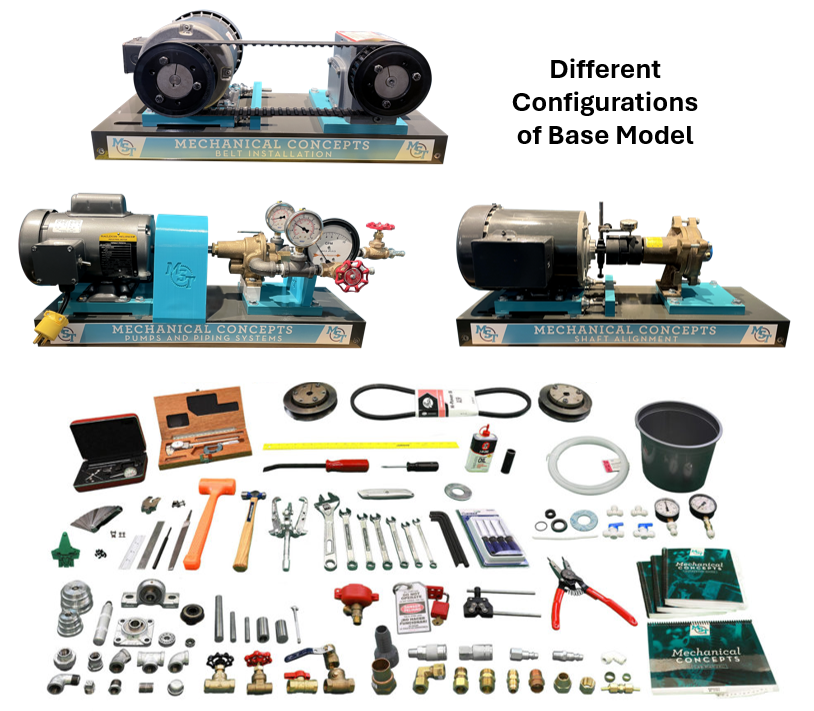

Training Simulator (1)

Portable workstation with industrial, real world plant components

Matches perfectly to Lab Guide with step by step instructions

Folds up for easy storage

Non-skid rubber feet

Dimensions: 25.25″ x 13.5″ x 10.5″

MST’s Mechanical Concepts Training provides a complete mechanical training course from a subject matter expert with decades of experience. Whether you choose to schedule onsite training or utilize our curriculum and simulator package, our customized training will provide your employees with hands-on experience and a full understanding of mechanical concepts. Start your customized mechanical concepts training today!

To learn more about our various Industrial Maintenance Training Programs including Maintenance Fundamentals Training, Industrial Electrical Training, Electrical Controls Training, Pneumatics Controls Training, Programmable Logic Control Training, or Analog Controls Training, contact us today.

General Safety Guidelines, Safety Strategies, Accident Investigation, Working Safely with Machinery, Other Safety Devices, Hazards Assessment and Prevention, Characterizing the Nature of Identified Hazards, Hazard Prevention and Control, Safety Audits, Regulatory Agencies and Abbreviations, Visual Safety

Steel Rules, Micrometers, Verniers, Vernier Height and Depth Gauges, Mechanical Dial Instruments, Digital Instruments, Telescoping Gauges

Antifriction Bearings, Bearing Design, Mounting of Bearings, Ball and Roller Bearings, Specialized Bearings, Bearing Maintenance and Installation

Function of Seals, Labyrinth Seals, Oil Seals, O-rings, Shaft Seal Installation, Sealing Requirements for Pumps, Mechanical Seals, Special Seals

Introduction to Belts, Important Terms and Definitions, Types of Belt Drives, Types of V-Belts, Sheaves and Pulleys, Belt Replacement, Tension Calculation of V-Belts, Job Completion Maintenance and Troubleshooting

History, Terminology, Safety, Codes and Standards, Chain Drives Versus Belt Drives, Chain Types Materials and Metric Incompatibility, Horizontal and Vertical Chain Drives, Sprockets, Chain Replacement, Maintenance

The History of Gears and Gear Drives, Definition of Gears, Codes and Standards, Gear Safety, Common Types of Gears, Open Gear Drives, Enclosed Gear Drives, Enclosed Gear Drive Configurations, Preventative Maintenance

Piping Systems and Fittings, Codes Designs and Safety, Piping Maintenance, Piping Materials and Fittings, Tubing, Tubing Connections, Tubing Maintenance, Hoses

Importance of Shaft Alignment, Symptoms of Misalignment, Types of Misalignment, Preparation for Shaft Alignment, Shaft Alignment Methods, Installation of Non-Precision Shaft Couplings, Aligning Shaft Couplings, Precision Coupling Alignment, Reverse Indicator Method Using Graphing, Alignment of Multiple Machines, Laser Alignment, Shaft Couplings, Types of Couplings, Special Types of Couplings, Coupling Selection, Preventative Maintenance, Safety

History of Pumps and Pumping Systems, Types of Pumping Systems, Centrifugal Pumps, Specialized Centrifugal Pumps, Special Chemical Pumps, Turbine and Propeller Pumps, Flow Patterns, Special Propeller Pumps, Rotary Pumps, Reciprocating Pump Application and Parts, Metering Pumps

Introduction to Centrifugal Pumps, Advantages and Disadvantages, Types of Centrifugal Pumps, Definitions of Pump Components, Types of Flow, Principles of Operation, Casing Materials and Configurations, Impellers, Impeller Suction, Characteristics of Centrifugal Pump Curves, Affinity Laws, Packing and Seals, Removing and Installing Packing and Seals, Packing Precautions, Mechanical Seals, Mechanical Seals Versus Packing, Types of Mechanical Seals, Installation of Mechanical Seals, Troubleshooting Packing and Seals

Let us design the perfect one for you.

© 2024. Multi-Skill Training Services, Inc.