Instructor Guide

Lesson Plans: a complete guide for the instructor that clearly describes the learning objectives, materials needed, and topics to be covered for each of the sessions

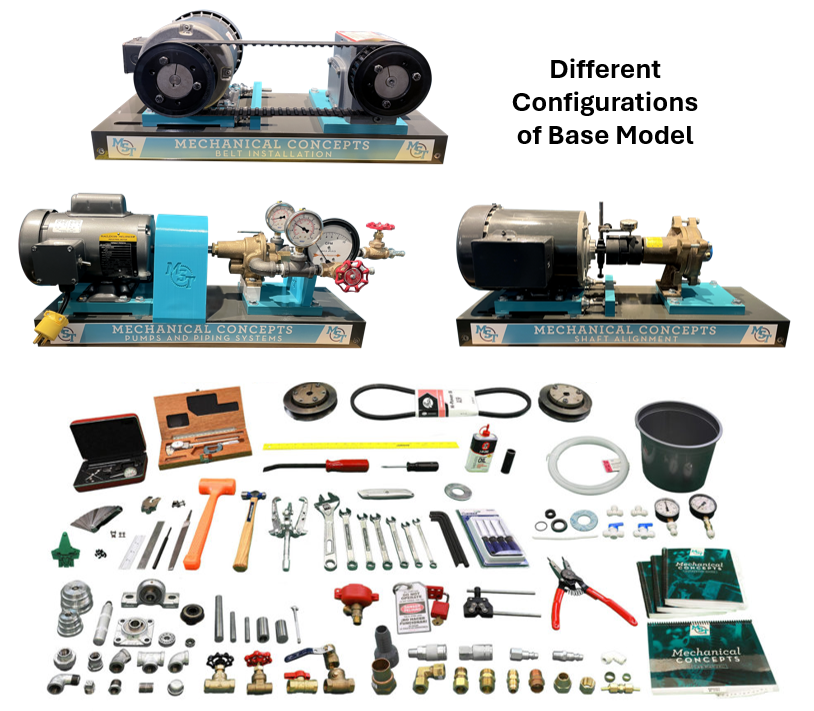

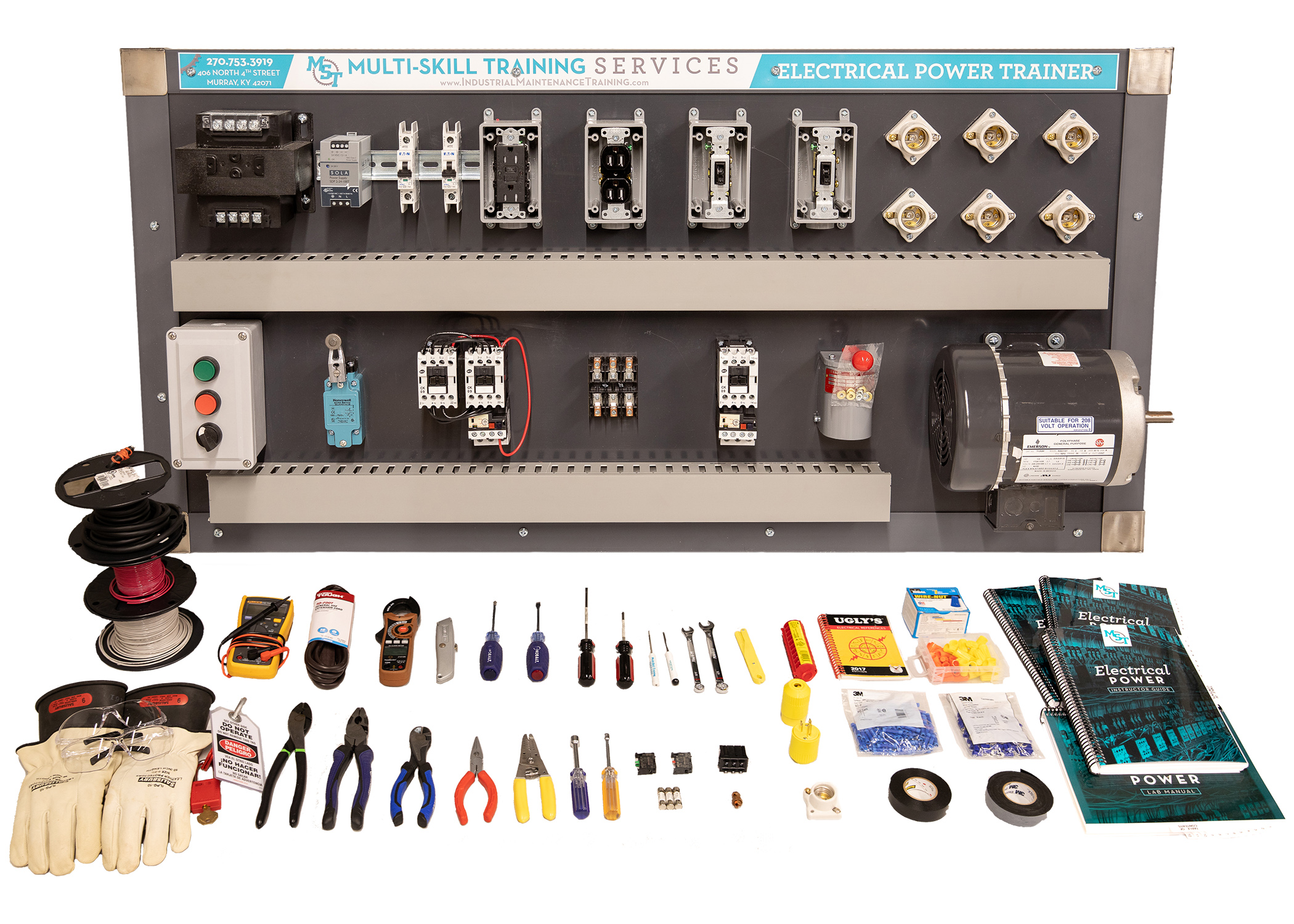

Lesson Content: text, images, and diagrams that help to demonstrate the concepts in the session

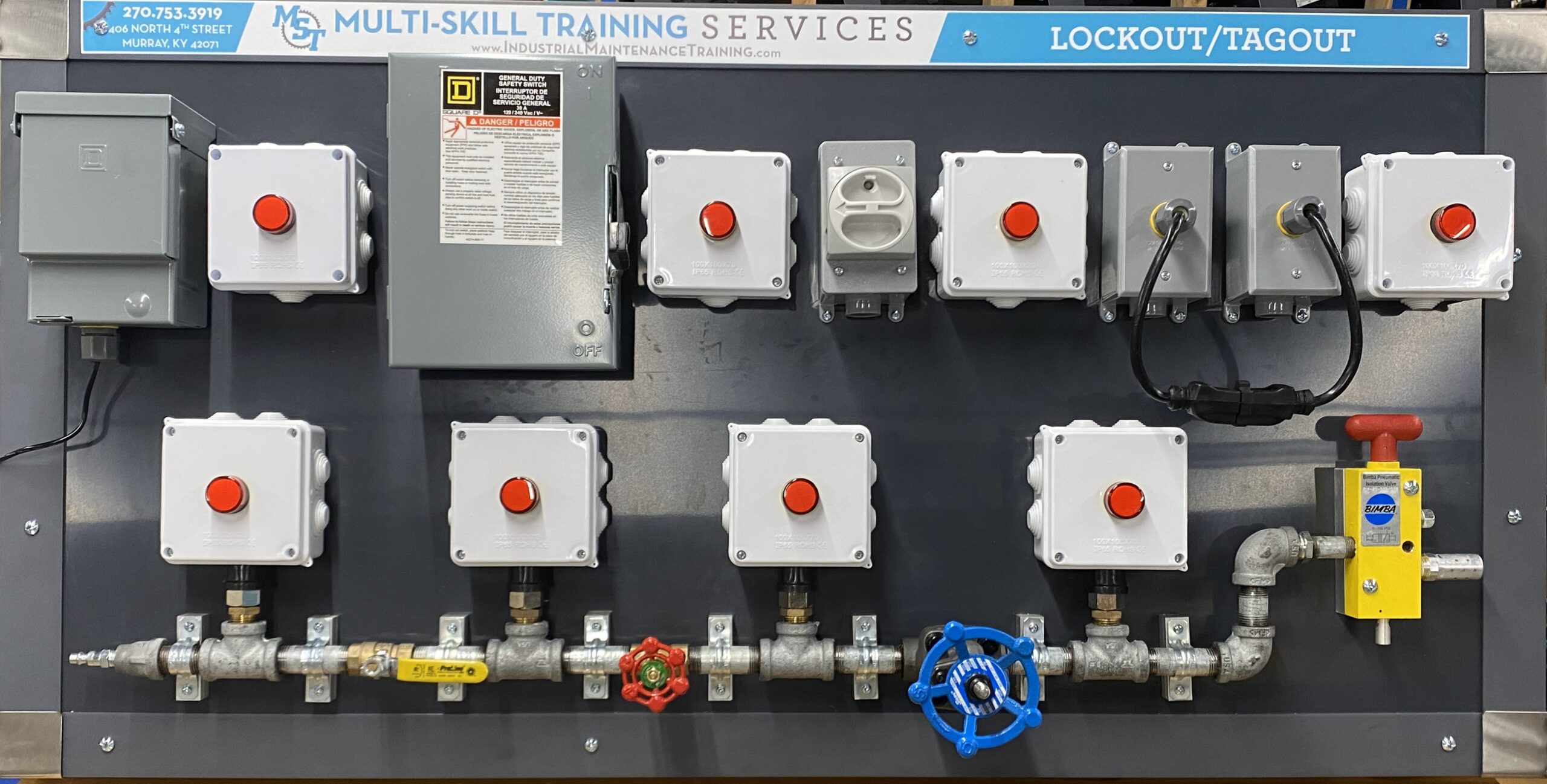

Hands-On Activities: each session includes instructions for each hands-on activity