Total Productive Maintenance (TPM), Part I

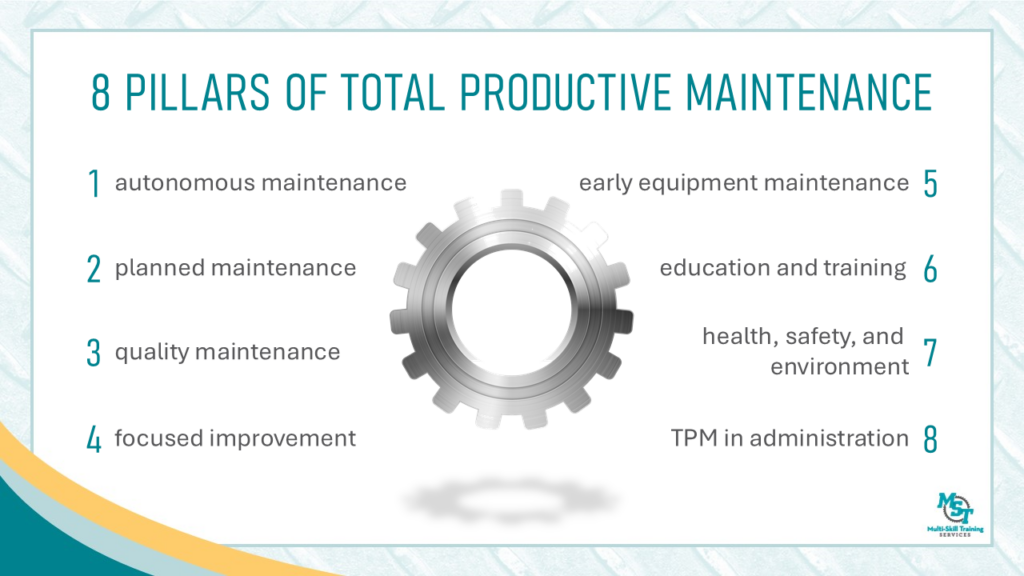

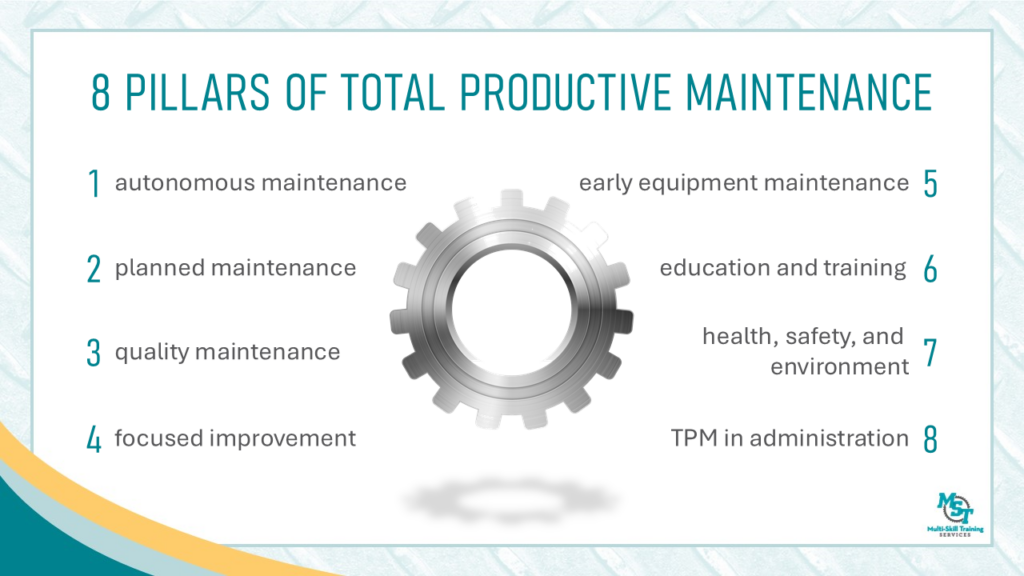

Total Productive Maintenance (TPM) is a comprehensive approach that emphasizes operator engagement in preventive and proactive strategies that will keep production running smoothly and efficiently. In this first discussion, we will investigate the eight foundational pillars of TPM and their impact on your productivity.

- AUTONOMOUS MAINTENANCE empowers machine operators to perform routine maintenance tasks, which will in turn improve equipment reliability, promote a sense of personal investment, reduce downtime, and increase overall operational efficiency. As operators get more familiar with the equipment, their skills improve, allowing the maintenance team to focus on more complex tasks.

- PLANNED MAINTENANCE involves scheduled, proactive equipment servicing to prevent breakdowns, optimize performance, and increase machinery lifespan, enhancing productivity and reliability. Maintenance activities are completed during slower production times or when planned interruptions are less consequential.

- QUALITY MAINTENANCE focuses on preventing defects and ensuring that products meet standards throughout production. It involves monitoring equipment conditions, standardizing processes, and training operators to detect and address potential issues early, enhancing overall product quality and minimizing downtime. This pillar works to find the root cause of the problem and eliminate it.

- FOCUSED IMPROVEMENT is a systematic approach aimed at eliminating production inefficiencies, such as equipment downtime, defects, and losses. It involves cross-functional teams identifying root causes of issues and implementing continuous improvement initiatives. This is an equipment Kaizen event where the team establishes a baseline performance level to measure any future improvements.

- EARLY EQUIPMENT MAINTENANCE utilizes proactive and preventive measures to extend the lifespan of industrial machinery. By addressing potential issues during the design and installation phases, it minimizes breakdowns, reduces downtime, and ensures smoother operations. It includes factors like how easy it is to clean, inspect, lubricate, and the ergonomic placement of controls for operators.

- EDUCATION AND TRAINING are essential for empowering employees with the skills to maintain equipment and improve overall efficiency. Training focuses on autonomous maintenance, problem-solving, and continuous improvement, ensuring that the team can identify and address potential issues before they escalate. Education and training should be a company-wide initiative that involves everyone at all levels of the organization.

- HEALTH, SAFETY, AND ENVIRONMENT strategies minimize risks and ensure worker well-being in industrial settings. These tactics support the consistent operation of a safe, sustainable work environment while maximizing productivity and equipment efficiency.

- TOTAL PRODUCTIVE MAINTENANCE IN ADMINISTRATION applies the foundational principles of TPM into office contexts as well as on the plant floor. Administrative TPM reinforces a teamwork mindset, acknowledging that all facets of the company must be equally committed to the proper functioning of whole system in order to operate with excellence. Everyone should be on the same page, and support teams need to recognize the benefits of these improvements, including those in administrative roles.

Stay tuned for the next article in the series, which will highlight the five s’s of TPM. Or if you’re eager to get moving on your TPM journey, we’re ready to connect! Contact us today to find out how we can help you move further, faster!