1. If you do not train employees on their specific job, they will establish their own behavior and standards.

We always start with a Job Analysis to define the critical tasks of a job and then develop training to target the skills necessary to support those tasks. This step is important because it clarifies the expectations of the job.

We have experienced countless examples where production operators may have resolved an issue once using a unique method, and then continue to use that method because they do not understand the downstream consequences to the quality of the product. We often find that they have very little training on the machine that they are operating and how their job plays a part in the overall process. This is why we spend time to capture the overall job duties and spend time developing content, including very specific videos that will help build knowledge of the job.

2. If you do not train employees correctly, they are likely to become disengaged.

When employees are not sure what to do, or they lack the skills to perform critical tasks, they start to do the minimum and “go along with the flow” in order to not be reprimanded.

We counter this effect by clearly evaluating what skills they need for their job, and then provide targeted training and hands-on practice to build those skills. Almost all employees become more engaged following these types of training sessions.

3. If you do not train employees, you may keep the ones who don’t care, and lose the ones who do.

There is a dangerous belief that some managers have: “If I train my employees better, they may leave.”

In our experience, the opposite is true. The employees who strive to learn and perform better will leave, and those that are there to punch the time clock may stay.

We believe most employers want to provide opportunities for those employees who want to learn and be better, and training is a tool to accomplish that.

4. Training employees leads to discussions that can help solve many problems, not only technical issues.

Another valuable byproduct of effective training in groups is that it facilitates conversations that may go beyond the technical realm of the training.

As employees become more engaged in the training, they may expose other issues involving process or management that can be improved.

5. Training that involves self-study, including targeted video and interactive quizzing, can greatly improve performance.

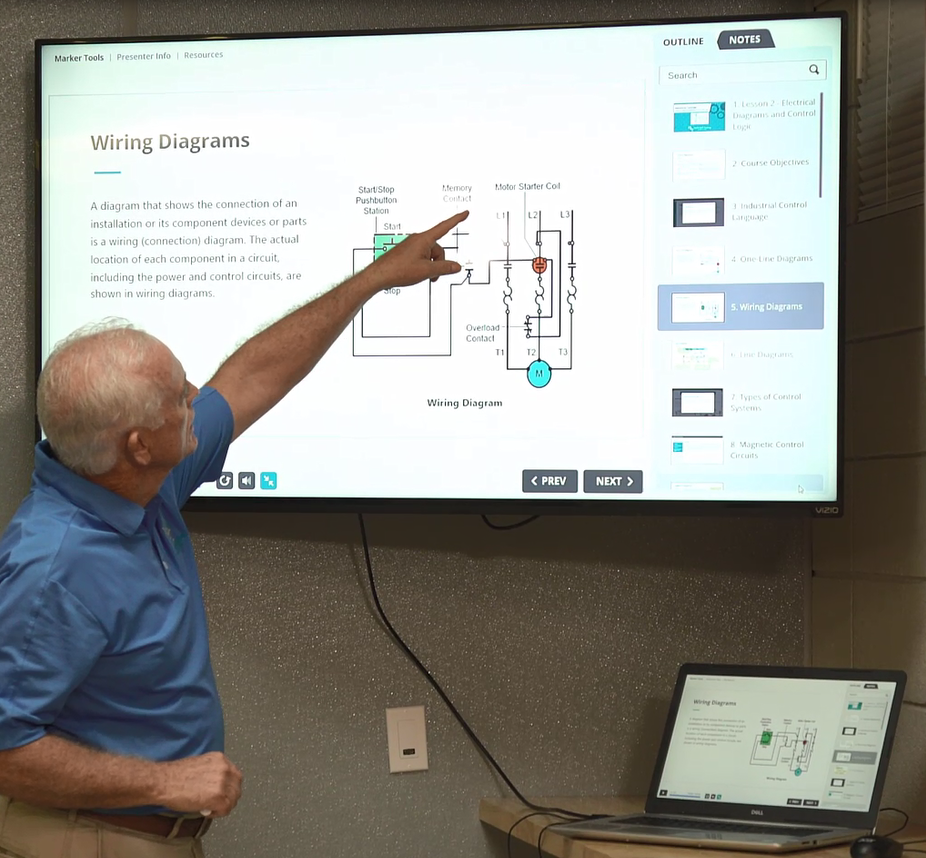

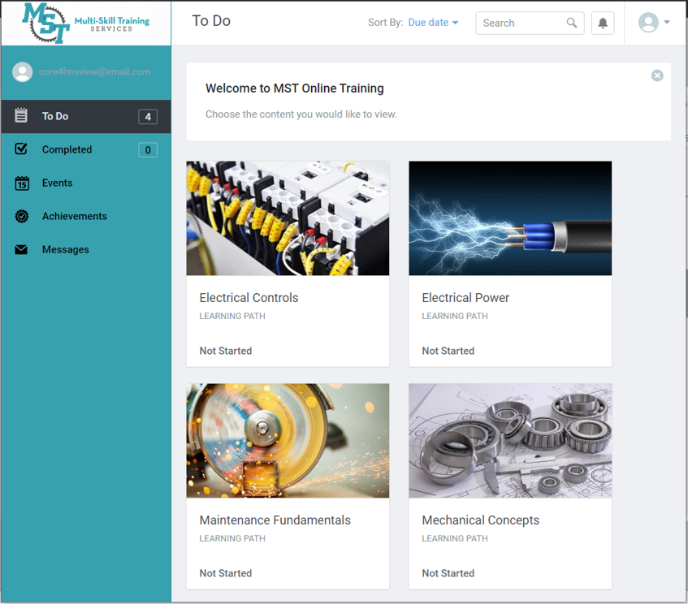

Our experience tells us that onsite training in groups works very well, especially given the opportunity for hands-on practice. Some learning, however, is best done by self-study. Therefore, we always push to provide self-paced online modules as supplemental modules to our hands-on training. These online modules allow the learner to get a custom experience that allows them to learn at their own pace. It also enables adaptive tutoring, which includes immediate coaching when they answer incorrectly. This type of experience is difficult in a classroom full of learners and is a great complement to hands-on training.

Let us design the perfect one for you.

© 2024. Multi-Skill Training Services, Inc.